The Energy Department just made one plutonium pit. Making more is uncertain

By Dylan Spaulding | October 10, 2024

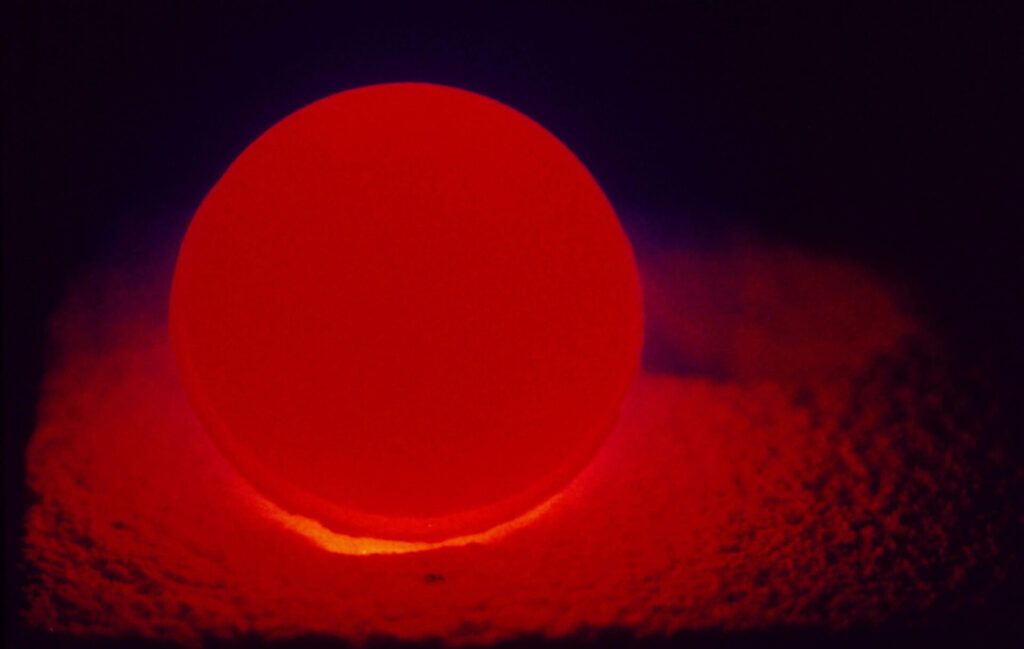

A pellet of dioxide of plutonium 238 used as a heat and power source glows under its own light. Most nuclear weapons have sphere-shaped pits made of plutonium 239 and with a gray color typical of metals. (Credit: US Energy Department public domain image)

A pellet of dioxide of plutonium 238 used as a heat and power source glows under its own light. Most nuclear weapons have sphere-shaped pits made of plutonium 239 and with a gray color typical of metals. (Credit: US Energy Department public domain image)

Two conflicting developments arose this month in US efforts to produce new plutonium pits for its nuclear weapons: The National Nuclear Security Administration (NNSA) announced it had produced a warhead-ready pit—the explosive core of a nuclear weapon—for the first time in decades, and a federal court ruled that NNSA will be required to consider the cumulative environmental and health impacts of its pit production program.

Overshadowing these events is a vigorous debate over the necessity for new pits at all. Previous analyses have found that plutonium pits have viable lifespans well beyond the expected service life of the current stockpile, whereas production of pits for new weapons is part of a sweeping US nuclear modernization that raises concern over the future of arms control and any possibility for stockpile reductions at a time of deteriorating international relations.

The two most recent developments illustrate a critical tension in the US nuclear weapons program: New pit production demonstrates a doubling down of US reliance on nuclear weapons for the 21st century. The failure to adhere to environmental policy in doing so highlights the unwitting cost that US citizens may bear for this policy choice—as they have repeatedly in the past.

Los Alamos “diamond-stamps” first plutonium pit. On October 1, NNSA announced that the Los Alamos National Laboratory had produced its first plutonium pit certified for use in the new W87-1 nuclear warhead. Pits that meet the exacting quality control standards for use in the US nuclear stockpile receive an indelible ink “diamond stamp” on the surface in what has become a traditional mark of certification.

This development was expected before the end of 2024 and demonstrates that, despite many difficulties, Los Alamos is making some progress toward its stated production goal of 30 pits per year by 2028. This is in fact a significant development: The United States has not made plutonium pits in any large quantity since 1989, when pit production at the Rocky Flats plant was halted. Even though Los Alamos did make a relatively small quantity of pits between 2007 and 2011, the lab has historically not played a large role in the actual production of weapon components, especially not for new weapon designs.

The start of plutonium pit production shows that Los Alamos is now moving ahead with bringing this controversial capability back: Processes and equipment have been fine-tuned, the chemistry and foundry processes have been mastered to alloy and cast plutonium, and these components can now be machined to required tolerances. But significant challenges remain.

Production challenges. Despite any fanfare, demonstrating the ability to certify one plutonium pit doesn’t guarantee smooth sailing toward Los Alamos’s mandated production goals.

The Los Alamos’ Plutonium Facility at Technical Area 55 (PF-4) is conducting the dangerous and difficult work of pit production while also undergoing construction and modernization, with work happening round-the-clock—several other plutonium-related missions are pursued under the same roof. The facility has been criticized for deficiencies in personal safety and safety-related engineering, including recent glovebox fires, floods, worker exposure to plutonium and beryllium, and violations of criticality safety rules. The likelihood of such incidents increases as a result of fast-paced work in close-quarters with a mostly new workforce. In 2013, the PF-4 facility was shut down for three years following a severe criticality safety violation; a repeat could prove fatal, literally and figuratively.

Production is likely to be slow at first, but is expected to increase over the coming years. While the first units being produced will likely continue to optimize efficiency and pace, not every pit is likely to meet stockpile requirements. Chemical or physical deficiencies could still result in some pits being sent back to the scrap bin every year. This will require Los Alamos to produce more pits per year to achieve 30 diamond-stamped pits per year for the W87-1.

Regardless of Los Alamos’ success, the congressionally mandated quota of 80 pits per year remains impossible to meet by NNSA’s own admission. This number relies on completion and commissioning of a second production facility at the Savannah River Site in South Carolina, which won’t be operational until the mid-2030s at the earliest.

Just as the future rate of plutonium pit production is uncertain, the missile these pits are intended for—the new Sentinel intercontinental ballistic missile—is also not likely to be completed on schedule. The troubled Sentinel project remains vastly over budget and behind schedule, putting its future at risk and making coordination of the warhead and missile difficult to foresee. Problems or changes in scope for either program will affect the other.

A federal court ruling. Coinciding with NNSA’s announcement of the first diamond-stamped pit, a US District Court ruled that the Energy Department and the NNSA violated the National Environmental Policy Act (NEPA) by failing to properly consider alternatives before proceeding with pit production, requiring the agency to conduct a programmatic environmental impact assessment.

This was a victory for transparency and the community groups—among them, Savannah River Site Watch, Nuclear Watch New Mexico, Tri-Valley Communities Against a Radioactive Environment (CAREs), and the Gullah/Geechee Sea Island Coalition—who, for years, have been asking for such an assessment.

Reestablishing pit production on the scale now contemplated is potentially the biggest investment in the nuclear weapons complex since the Manhattan Project. With it comes hiring and training of thousands of new employees, increased transportation between sites, new construction, safely handing radioactive material, and the generation of new nuclear waste. The cumulative nature of these activities, occurring across many Energy Department’s sites, demands that the impacts of pit production be considered holistically in the form of a programmatic environmental impact assessment.

The environmental impact statements issued by the national laboratories offer perhaps the best public-facing analyses of whether their plans comply with standards for protection of public safety and the environment, including the likelihood of specific scenarios and associated risk of public exposure to hazards such as chemicals or radiation. Still, the NNSA has—until now—resisted issuing such a programmatic statement.

The agency clearly recognizes that pit production involves much of the US nuclear weapons complex. The press release announcing the first diamond-stamped pit thanked workers in Kansas City, Lawrence Livermore National Labs, Los Alamos, and the Pantex plant in Texas. But the NNSA has so far relied on a series of addenda and supplements to a 2008 environmental impact statement for work at Los Alamos and considers Savannah River separately. These assessments largely ignore the cross-complex collaboration required and the subsequent risks, including impacts on the potentially overburdened Waste Isolation Pilot Plant in New Mexico that must absorb the prolific—and complex—waste stream from the pit production process.

The court ruling—which holds that the Energy Department and the NNSA did not follow environmental requirements in pursuing two production sites—will require the NNSA to conduct a new review, bringing renewed public scrutiny and allowing a new opportunity for input from concerned opponents.

An unclear horizon. A programmatic environmental impact statement can take years before it’s finalized. The judge in the case declined to halt construction at NNSA’s second pit production site at Savannah River while the new assessment is being carried out, and the two parties have until October 21st to seek an agreement. It’s likely that the NNSA will argue that stopping pit-production work would be too expensive, too disruptive, and too damaging to national security to consider. It remains unclear what the potential consequences could be if the NNSA decides to challenge the ruling.

While work at Los Alamos is likely to continue amid a programmatic assessment, design choices are still underway at the Savannah River Site, where the NNSA is attempting to retrofit the troubled former mixed oxide (MOX) fuel fabrication plant which never reached productivity despite more than $7 billion of investment. This site is years away from being active and will require extensive transformation that may cost as much as $25 billion. Given this enormous investment, a programmatic environmental impact statement can ensure that this transformation better addresses the actual hazards and better protects communities, workers, and the environment.

Reestablishing pit production in the United States is a massive undertaking. It involves resurrecting a lost capacity that requires complicated engineering, construction, and extremely hazardous work processes that will be carried out by a largely new work force with little to no prior experience. NNSA and its contractors must manage safety risks across multiple sites where new hazardous waste will be generated in communities that don’t want it and where the Energy Department has a poor historic track record of environmental stewardship.

Congress and the Biden administration should eliminate the mandated 80 pit per year requirement while the NNSA conducts a new, thorough environmental assessment that would go a long way toward promoting increased safety and public protection—a challenge that the NNSA and the labs should take seriously.

Together, we make the world safer.

The Bulletin elevates expert voices above the noise. But as an independent nonprofit organization, our operations depend on the support of readers like you. Help us continue to deliver quality journalism that holds leaders accountable. Your support of our work at any level is important. In return, we promise our coverage will be understandable, influential, vigilant, solution-oriented, and fair-minded. Together we can make a difference.

Dylan, thank you. I would add a couple of notes. First, in the second paragraph you have the claim that there is “vigorous debate” about “the necessity for new pits at all.” A time frame should be specified. Indeed, nobody is saying that new pits are needed right now for the stockpile. (That is one of the reasons why pit production at LANL is a dubious investment and gratuitous suite of environmental impacts, but we’ll come to that.) But saying no new pits are needed “at all” is tantamount to saying nuclear warheads aren’t needed “at all.” I would agree,… Read more »

In my previous comment I should have added a note about the “at least 80” pit per year requirement, which you (Dylan) say should be eliminated. As you say, everybody including NNSA agrees that NNSA cannot create the capability to make 80 ppy by 2030. So the schedule at least is absurd. So is “at least 80 ppy” too much? It’s hard to say. For a much smaller arsenal, yes it is too big. But the decision to have a much smaller arsenal would have to be made first. That is very far from happening. Meanwhile NNSA is faced with… Read more »